- March 6, 2024 11:00 pm

- Amritsar -I, Punjab, India

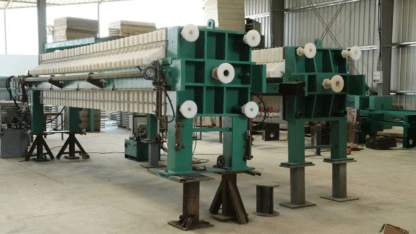

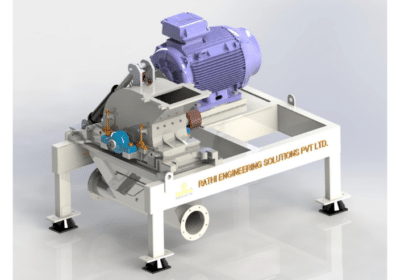

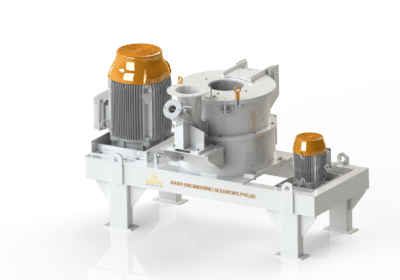

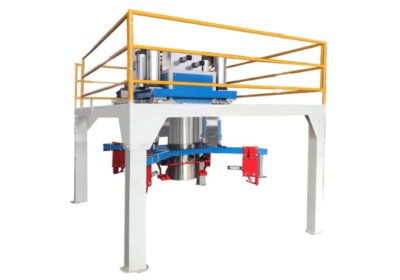

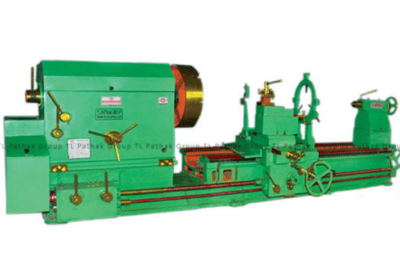

A corrugation machine, also known as a corrugator, is a vital piece of equipment in the manufacturing of corrugated cardboard. Corrugated cardboard, with its distinctive fluted layer sandwiched between two flat liners, is widely used in packaging for its strength, durability, and versatility.

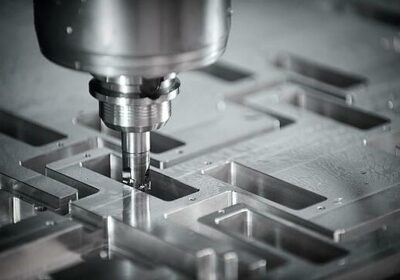

The corrugation process begins with the production of the fluted layer, which is typically made from a continuous roll of paper called linerboard. This linerboard is fed into the corrugator, where it passes through a series of heated rollers and corrugating rolls. These rolls are carefully engineered with a pattern of ridges and valleys that impart the characteristic wavy shape to the paper, creating the corrugated medium.

Meanwhile, the flat liners, usually made from thicker paperboard or cardboard, are unwound from separate rolls and brought together with the corrugated medium to form what is known as a single facer. The single facer is a crucial component of the corrugator, as it bonds the liners to the corrugated medium using adhesive while maintaining the desired alignment and tension.

Once the single facer has securely bonded the liners to the corrugated medium, the resulting corrugated board passes through a series of heated platens or hot plates to cure the adhesive and ensure a strong bond. After curing, the corrugated board may undergo additional processing steps such as slitting, cutting, and stacking before being shipped to customers for use in packaging applications.

Corrugation machines come in various configurations and sizes to accommodate different production requirements. Some are designed for high-speed, continuous operation, capable of producing large volumes of corrugated board in a short amount of time, while others are smaller and more suitable for smaller-scale or specialty applications.

In addition to manufacturing new corrugated board, corrugation machines can also be used to recycle used cardboard into new corrugated material, contributing to sustainability efforts by reducing waste and conserving resources.

Overall, corrugation machines play a critical role in the production of corrugated cardboard, providing the strength and durability needed for a wide range of packaging applications. Through precision engineering and efficient operation, these machines help meet the growing demand for sustainable packaging solutions in industries around the world.

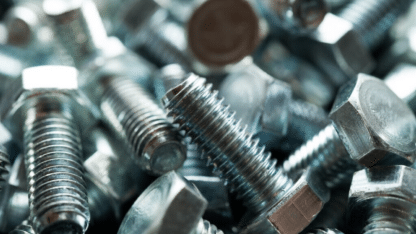

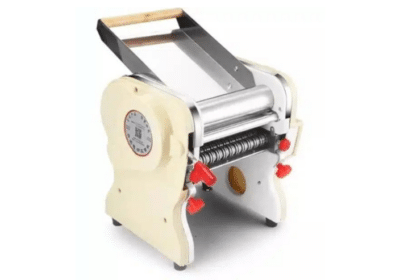

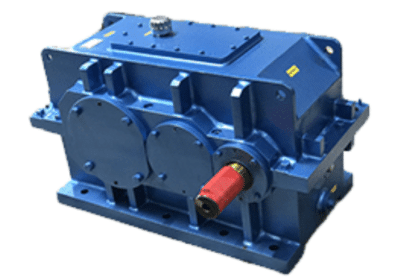

Machine is having special characteristic of oil tub equipment machine with oil lubricating pump

Gadget is outfitted with heavy obligation excel makes P.I.V. tools container

Imported chain to regulate the duration of the sheet to be cut with gear Ratio 1:5

Machine is driven by means of A.C. frequency pressure with provision for synchronization of speed between Sheet Cutter with Corrugating system

Contact us today to learn more!

Name: Friends Engineering Company

Phone: 9646555550

Address: 390-B, FOCAL POINT, Mehta Rd, Amritsar, Punjab 143001

Website: https://www.friendsenggco.com

Connect with our Social Media Channels:

Facebook: https://facebook.com/Platenpunchingmachines/

Twitter: https://twitter.com/friends_engg

Instagaram : https://www.instagram.com/friendsenggco/

YouTube: https://www.youtube.com/c/FriendsEngineeringCompany

Linkedin: https://www.linkedin.com/company/friends-engineering-co

Overview

- Category: Industrial Machinery & Tools

- 31 views

- Add to Favourites

- Report Abuse

-

Share this Ad:

Seller Information

Please login to view the seller information.

Location

Related Ads

Buy JPT F10 Wash Pressure Online

- 1 day ago

- Indore City, Madhya Pradesh, India

- 6 Views

Efficient Sugarcane Juice Maker Machine For Freshly Extracted Refreshment

- 4 days ago

- Indore City, Madhya Pradesh, India

- 11 Views

Introducing Our Bar Cutting Machine – Precision at Every Cut

- 4 days ago

- Delhi Cantonment, Delhi, India

- 9 Views

Strut Support Systems and Channel Bractery and Fittings Manufacturers

- 4 days ago

- Ludhiana (East), Punjab, India

- 11 Views

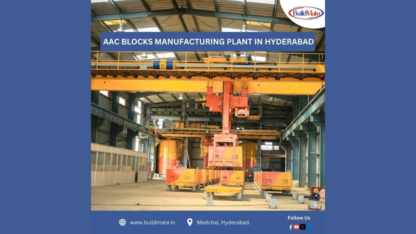

AAC Blocks Manufacturing Plant in Hyderabad

- 1 week ago

- Hyderabad - Medchal, Telangana, India

- 13 Views

Leading Heating Coil Manufacturers in India

- 2 weeks ago

- Bengaluru - Agara, Karnataka, India

- 20 Views

Crusher Plants Machine Manufacturer in India

- 2 weeks ago

- Hyderabad - Medchal, Telangana, India

- 14 Views

Buy Top Notch Circular Saw | BIPICO

- 2 weeks ago

- Mumbai - Churchgate, Maharashtra, India

- 14 Views

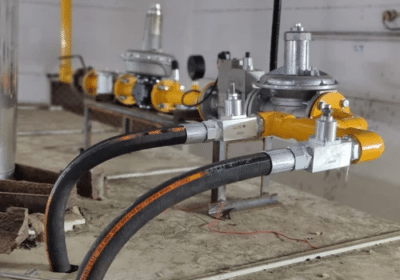

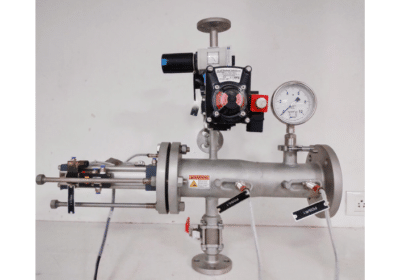

Gas Train Solution

- 3 weeks ago

- Noida City, Uttar Pradesh, India

- 23 Views

Best Laminar Air Flow Cabinet Manufacturers in India

- 4 weeks ago

- Ambala City, Haryana, India

- 25 Views

4 Wheel Shopping Trolley – Upgrade Your Grocery Game!

- 4 weeks ago

- Singapore

- 16 Views

Ring Stretch Wrapping Machine

- 4 weeks ago

- Ahmadabad City, Gujarat, India

- 22 Views

Check Out Scissor Lift Rental Rates in Singapore

- 4 weeks ago

- Singapore

- 21 Views

Best Forged Elbow Fitting Near Me Online in India

- 4 weeks ago

- Mumbai - Borla, Maharashtra, India

- 25 Views

Barometer Circular Manufacturer Supplier and Exporter

- 4 weeks ago

- Sweden

- 17 Views

Super Duplex Gate Valve Supplier in Egypt

- 4 weeks ago

- Nigeria

- 23 Views

Cone Crusher Manufacturer in India

- 4 weeks ago

- Hyderabad - Medchal, Telangana, India

- 15 Views

Highest Grade Hacksaw Blades

- 1 month ago

- Mumbai - Churchgate, Maharashtra, India

- 32 Views

Manufacturers of Reverse Osmosis Plant and Industrial RO Plant

- 1 month ago

- Gautam Buddha Nagar City, Uttar Pradesh, India

- 27 Views

Stone Crushing Plant Manufacture in Hyderabad

- 1 month ago

- Hyderabad - Medchal, Telangana, India

- 23 Views

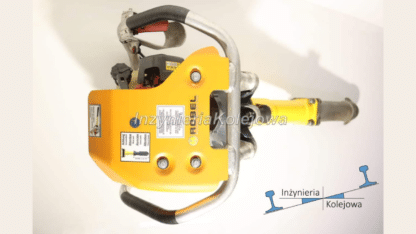

Cembre LD1P Petrol Rail Drill For Sale

- 1 month ago

- Poland

- 28 Views

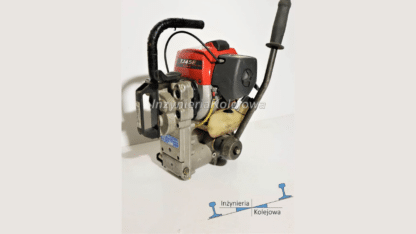

Master 35 Petrol Screwdriver For Sale

- 1 month ago

- Poland

- 25 Views

Geismar MP12 Railway Grinder For Sale

- 1 month ago

- Poland

- 30 Views

Atlas Copco Cobra TT Breaker For Sale

- 1 month ago

- Poland

- 31 Views

Boring Milling Machine | Ray Mechatronics

- 1 month ago

- Bengaluru - Peenya, Karnataka, India

- 15 Views

Gas Post Driver – Revolutionizing Fencing Projects with Power and Precision

- 2 months ago

- Canada

- 24 Views

Surge Anticipator Valve Supplier in Nigeria

- 2 months ago

- Nigeria

- 31 Views

Buy TCT Cutting Tools at The Best Prices Today!

- 2 months ago

- Navsari City, Gujarat, India

- 26 Views

Premium Ferro Titanium Lumps For Industrial Use

- 2 months ago

- Rajendra Nagar, Delhi, India

- 32 Views

Purchase Best Quality SS Fasteners in India

- 2 months ago

- Mumbai - Nariman Point, Maharashtra, India

- 38 Views

Top Metal Detectors in Jaipur

- 2 months ago

- Jaipur City, Rajasthan, India

- 37 Views

AAC Plant Machine Manufacturers

- 2 months ago

- Hyderabad - Medchal, Telangana, India

- 34 Views

Reliable Ferro Alloys Suppliers | Bansal Brothers

- 2 months ago

- Delhi Cantonment, Delhi, India

- 23 Views

Semi-Automatic Digital Liquid Filling Machine

- 2 months ago

- Kolkata - Brace Bridge, West Bengal, India

- 33 Views

Oil Extraction Machine Manufacturers | Andavar Lathe Works

- 2 months ago

- Erode City, Tamil Nadu, India

- 28 Views

Paper Cutting Machine | Friends Engineering Company

- 2 months ago

- Amritsar -I, Punjab, India

- 29 Views

Top Uni Directional Knife Gate Valve Supplier in Nigeria

- 2 months ago

- Nigeria

- 46 Views

Uni Directional Knife Gate Valve Supplier in Nigeria

- 2 months ago

- Nigeria

- 22 Views

Die Cutting Machine | Friends Engineering Company

- 2 months ago

- Amritsar -I, Punjab, India

- 33 Views

Thermal Lamination Machine | Friends Engineering Company

- 2 months ago

- Amritsar -I, Punjab, India

- 35 Views

Carbon Steel ASTM A694 Flanges Stockists in Mumbai

- 2 months ago

- Mumbai - Byculla, Maharashtra, India

- 26 Views

Next Flat Belt Conveyor

- 2 months ago

- Gurgaon (Gurugram) City, Haryana, India

- 40 Views

Food Product Packing Machine – Industry Packaging

- 2 months ago

- Singapore

- 23 Views

Buy Top-Notch SS Fasteners in India

- 2 months ago

- Mumbai - Aare, Maharashtra, India

- 31 Views

Horizontal Injection Moulding Machine in India

- 2 months ago

- Sonipat City, Haryana, India

- 33 Views

Automatic Flow Wrap Machine

- 2 months ago

- Kolkata - Brace Bridge, West Bengal, India

- 28 Views

Highest-Grade Holesaw From BIPICO

- 2 months ago

- Mumbai - Aare, Maharashtra, India

- 31 Views

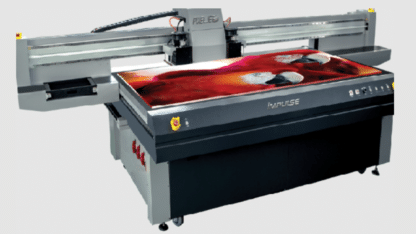

UV Flatbed Printing Machine

- 2 months ago

- Naraina Vihar, Delhi, India

- 32 Views

Paver Tiles and Concrete Blocks Making Machine in Pakistan

- 2 months ago

- Pakistan

- 29 Views

Concrete Blocks and Paver Tiles Making Machine in Pakistan

- 2 months ago

- Pakistan

- 26 Views

Discover Top Quality Metal Detectors

- 2 months ago

- Jaipur City, Rajasthan, India

- 29 Views

Top Concrete Blocks and Paver Tiles Making Machine

- 2 months ago

- Pakistan

- 33 Views

Paver Tiles and Concrete Blocks Making Machine

- 2 months ago

- Pakistan

- 49 Views

Best Concrete Blocks and Paver Tiles Making Machine

- 2 months ago

- Pakistan

- 37 Views

Surf Making Machine

- 2 months ago

- Varanasi City, Uttar Pradesh, India

- 36 Views

Concrete Blocks and Paver Tiles Making Machine

- 2 months ago

- Pakistan

- 38 Views

Glass Printing Machine From Pixeljet

- 2 months ago

- Naraina Vihar, Delhi, India

- 26 Views

KM Mughal Concrete Paver Tiles and Blocks Making Machine

- 2 months ago

- Pakistan

- 32 Views

Buy High Quality SS Shims in India

- 2 months ago

- Mumbai - Vikroli, Maharashtra, India

- 20 Views

Alrouf-Xummit Series Portable Light Tower

- 2 months ago

- Saudi Arabia

- 24 Views

Buy Quality SS Fasteners in India

- 2 months ago

- Mumbai - Andheri, Maharashtra, India

- 27 Views

Pneumatic Actuated Gate Valve Supplier in Nigeria

- 3 months ago

- Nigeria

- 30 Views

Leading Metal Detectors in Jaipur | SS Communications

- 3 months ago

- Jaipur City, Rajasthan, India

- 36 Views

120kg Fiber Baling Machine | Essar Engineers

- 3 months ago

- Coimbatore North, Tamil Nadu, India

- 45 Views

Honing Machine Manufacturers | Abhi Fine Products

- 3 months ago

- Coimbatore North, Tamil Nadu, India

- 31 Views

Vertical Honing Machine | Abhi Fine Products

- 3 months ago

- Coimbatore North, Tamil Nadu, India

- 41 Views

Shrink Tunnel Wrapping Machine

- 3 months ago

- Kolkata - Brace Bridge, West Bengal, India

- 32 Views

Revolutionize Your Bakery – Top Commercial Dough Mixers in India | Mangal Machines

- 3 months ago

- Patiala City, Punjab, India

- 36 Views

Drill Rig Machine | REL

- 3 months ago

- Coimbatore North, Tamil Nadu, India

- 28 Views

DTH Drilling Rig Manufacturers | REL

- 3 months ago

- Coimbatore South, Tamil Nadu, India

- 39 Views

Upgrade Your Production Line – Cookies Making Machines Tailored For Indian Market

- 3 months ago

- Chandigarh City, Chandigarh, India

- 39 Views

Mild Steel Automatic Water Cooling Conveyor | RDR Taichi

- 3 months ago

- Gurgaon (Gurugram) City, Haryana, India

- 34 Views

Stainless Steel Self Drilling Screws | Ejot

- 3 months ago

- Gurgaon (Gurugram) City, Haryana, India

- 31 Views

Allen-Bradley 20Ce261A0Annbng0 Frequency Drive | Auto2Mation

- 3 months ago

- New Jersey, USA

- 47 Views

Control Valve Supplier in Nigeria | African Valve

- 3 months ago

- Nigeria

- 33 Views

Storage Solutions Companies in India | Bhupati Engineering

- 3 months ago

- Ambala City, Haryana, India

- 64 Views

Filter Press Manufacturers Coimbatore | GTS Enviro

- 3 months ago

- Coimbatore North, Tamil Nadu, India

- 55 Views

Top-Rated UV Dryers Available in India | SASG UV Solutions

- 3 months ago

- Faridabad City, Haryana, India

- 31 Views

Jetsci Digital Label Printing Machine

- 3 months ago

- Gurgaon (Gurugram) City, Haryana, India

- 49 Views

Conveyors and Belts | Eminent Packs

- 3 months ago

- Kolkata - Brace Bridge, West Bengal, India

- 34 Views

Injection Molding Machines For Food Box Crates | China Sanshun

- 3 months ago

- China

- 54 Views

Wholesale Rubber Mold Manufacturing | Rubber Molds and Products

- 3 months ago

- Canada

- 41 Views

Largest Supplier of High Quality Magnets and Magnetic Tools in Australia | AMF Magnetics

- 3 months ago

- Australia

- 47 Views

Ferro Titanium Cored Wire | Bansal Brothers

- 3 months ago

- Bhilai, Chhattisgarh, India

- 53 Views

The JPT 550NM Impact Wrench Solution For Automotive Repairing

- 3 months ago

- Indore City, Madhya Pradesh, India

- 47 Views

Efficient Dewatering Solutions with Pumps in Ghana

- 4 months ago

- Faridabad City, Haryana, India

- 34 Views

Elevate Your Success with Premium Work Platforms

- 4 months ago

- Australia

- 43 Views

AAC Block Making Machine Manufacturers in India

- 4 months ago

- Hyderabad - Medchal, Telangana, India

- 36 Views

Impact Extrusion Manufacturer

- 4 months ago

- Gurgaon (Gurugram) City, Haryana, India

- 36 Views

PP Yarn Cutting Machine

- 4 months ago

- Ahmadabad City, Gujarat, India

- 52 Views

Carpet Cleaner Machine | Aman Cleaning Equipments

- 4 months ago

- Noida City, Uttar Pradesh, India

- 60 Views

Shrink Wrap Machine Supplier in Jammu | Hindustan Bottling and Engineers

- 4 months ago

- Noida City, Uttar Pradesh, India

- 51 Views

Submersible Dewatering Pump in Coimbatore | Cosmos Pumps

- 4 months ago

- Faridabad City, Haryana, India

- 53 Views

Pouch Packing Machine Manufacturer in Faridabad | Durga Packaging Machine

- 4 months ago

- Noida City, Uttar Pradesh, India

- 37 Views

Hanna Multiparameter – Measuring parameters | Chemstock

- 4 months ago

- UAE

- 47 Views

Dump Chocks – Safeguarding Canada Industries | TopRops

- 4 months ago

- Canada

- 39 Views

TATA Agrico Self Drilling Screws | 3SGroups

- 5 months ago

- Dindigul City, Tamil Nadu, India

- 63 Views

CENTAMAX Coupling / RICH ARCUSAFLEX Coupling / VULKAN Coupling / CENTAFLEX Coupling | Seawide

- 5 months ago

- UAE

- 66 Views

Forklift | SFS Equipments

- 5 months ago

- Bengaluru - Lingarajapuram, Karnataka, India

- 50 Views

Toprops – Ensuring Safety with ROPS and FOPS in Canada

- 5 months ago

- Canada

- 49 Views

Buy SS Round Bars | Hans Metal India

- 5 months ago

- Mumbai - Aare, Maharashtra, India

- 49 Views

The JPT Brushless Cordless Drill to Make Your Projects a Breeze

- 5 months ago

- Indore City, Madhya Pradesh, India

- 42 Views

Gerber Centrifuge Machine For 24 Test | Cowbell

- 5 months ago

- Ambala City, Haryana, India

- 81 Views

Vibro Sifter | Cybernetik Technologies

- 5 months ago

- Pune City, Maharashtra, India

- 65 Views

Big Deal on JPT F10 Wash Pressure Online

- 5 months ago

- Indore City, Madhya Pradesh, India

- 56 Views

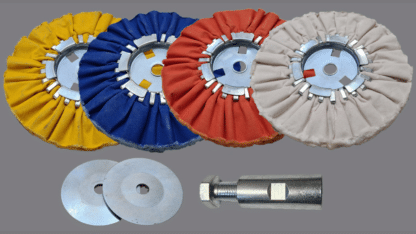

Polishing Wheels and Tapered Spindle Products | Polish Up

- 5 months ago

- Australia

- 55 Views

Don’t Miss Out – Grab The JPT Cordless Impact Wrench at a Steal

- 5 months ago

- Indore City, Madhya Pradesh, India

- 69 Views

Nickel Strips Stockist | Technolloy Inc.

- 5 months ago

- Mumbai - Dadar, Maharashtra, India

- 59 Views

Chest Freezer | Elanpro

- 5 months ago

- Gurgaon (Gurugram) City, Haryana, India

- 70 Views

Ice Cube Machine | Elanpro

- 5 months ago

- Gurgaon (Gurugram) City, Haryana, India

- 64 Views

Traffic Safety Equipments Exporters | MachinesEquipments

- 5 months ago

- Nigeria

- 58 Views

Ingot Mold From Anshan Metal Co. Ltd.

- 5 months ago

- China

- 62 Views

Flexible Low Alloy Steel Hand Hacksaw Blades | BIPICO

- 5 months ago

- Mumbai - Bandra, Maharashtra, India

- 89 Views

Crusher Spare Parts From Anshan Metal Co. Ltd.

- 5 months ago

- China

- 171 Views

Pixeljet® Asbestos Sheets Printing Machines

- 5 months ago

- Naraina Vihar, Delhi, India

- 60 Views

Asbestos Sheets Printing Machines | Pixeljet®

- 5 months ago

- Naraina Vihar, Delhi, India

- 44 Views

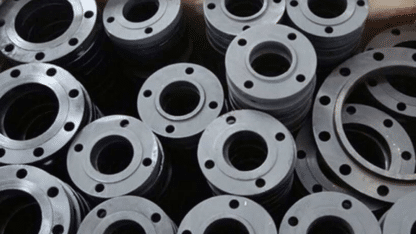

Carbon Steel ASTM A105 Flanges Manufacturers | Ganpat Metal Industries

- 5 months ago

- Mumbai - Andheri, Maharashtra, India

- 142 Views

Industrial Temperature Sensors | Nexthermal

- 5 months ago

- Bengaluru - Agara, Karnataka, India

- 79 Views

Top PCC Panel Exporter in India | Eletechnics

- 6 months ago

- Faridabad City, Haryana, India

- 67 Views

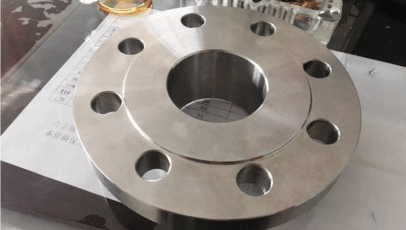

Inconel 600 Flanges Suppliers in India | Deep Steel Centre

- 6 months ago

- Mumbai - Chowpatti, Maharashtra, India

- 73 Views

Forklift Rental Service | SFS Equipments

- 6 months ago

- Bengaluru - Lingarajapuram, Karnataka, India

- 156 Views

Liquid Filling Line For Sale in Pakistan

- 6 months ago

- Pakistan

- 68 Views

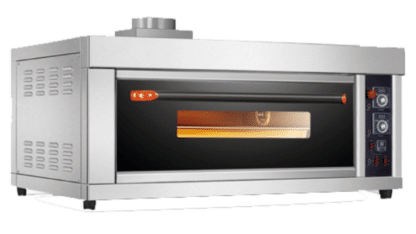

Looking For Best Baking Oven?

- 6 months ago

- Jaipur City, Rajasthan, India

- 71 Views

Centrifuge Bag Manufacturers | Makpol Industries

- 6 months ago

- Ghaziabad City, Uttar Pradesh, India

- 74 Views

Double Column VMC Machine | Ray Mechatronics

- 6 months ago

- Bengaluru - Peenya, Karnataka, India

- 95 Views

Cement Block Manufacturing Machine | BuildMate

- 6 months ago

- Hyderabad - Medchal, Telangana, India

- 87 Views

High Pressure Valve Manufacturers | Sap Industries Ltd.

- 6 months ago

- Ahmadabad City, Gujarat, India

- 55 Views

Engineering Temperature Sensors | Nexthermal

- 6 months ago

- Bengaluru - Agara, Karnataka, India

- 86 Views

Rental Material Handling Equipment | SFS Equipments

- 6 months ago

- Bengaluru - Lingarajapuram, Karnataka, India

- 63 Views

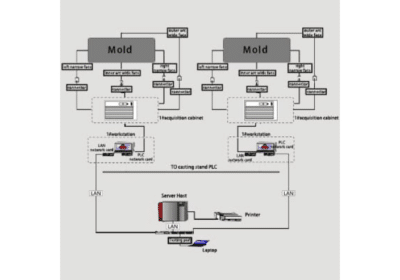

Mold Breakout Prediction System | Wuhan CenterRise M&C Engineering CO.Ltd.

- 7 months ago

- China

- 80 Views

Automatic Strip Cutting Machine | Suba Solutions

- 7 months ago

- Chennai - Vandalur, Tamil Nadu, India

- 114 Views

Jacketed Vessel Manufacturer | Mekark Industry

- 7 months ago

- Chennai - Ashok Nagar, Tamil Nadu, India

- 84 Views

5 Fit Stainless Steel Working Table | Mix Kitchen International

- 7 months ago

- Nigeria

- 91 Views

5 Fit Stainless Steel Bread Cooling Rack | Mix Kitchen International

- 7 months ago

- Nigeria

- 45 Views

Popcorn Machine | Mix Kitchen International

- 7 months ago

- Nigeria

- 81 Views

4 Doors Industrial Refrigerator | Mix Kitchen International

- 7 months ago

- Nigeria

- 75 Views

4 Fit Stainless Steel Working Table | Mix Kitchen International

- 7 months ago

- Nigeria

- 101 Views

10 Litters Cake Mixer Machine | Mix Kitchen International

- 7 months ago

- Nigeria

- 75 Views

Bread Slicer Machine | Mix Kitchen International

- 7 months ago

- Nigeria

- 53 Views

Industrial Sink 3 Tanks | Mix Kitchen International

- 7 months ago

- Nigeria

- 51 Views

3 Burners Industrial Gas Shawarma Machine | Mix Kitchen International

- 7 months ago

- Nigeria

- 51 Views

4 Burners Industrial Electric Cooker with Oven | Mix Kitchen International

- 7 months ago

- Nigeria

- 99 Views

Chin Chin Cutting Machine | Mix Kitchen International

- 7 months ago

- Nigeria

- 52 Views

5 Plates Food Warmer Display Machine | Mix Kitchen International

- 7 months ago

- Nigeria

- 61 Views

24 Trays Food Dehydrator Machine | Mix Kitchen International

- 7 months ago

- Nigeria

- 58 Views

Dewatering Pumps Nigeria | Cosmos Pumps

- 7 months ago

- Faridabad City, Haryana, India

- 67 Views

32 Trays Rotary Rack Oven / 50 Kg Rotary Rack Oven | Mix Kitchen International

- 7 months ago

- Nigeria

- 65 Views

Pure Water Machine | Mix Kitchen International

- 7 months ago

- Nigeria

- 59 Views

Ice Cream Machine | Mix Kitchen International

- 7 months ago

- Nigeria

- 62 Views

Cake Showcase Machine | Mix Kitchen International

- 7 months ago

- Nigeria

- 58 Views

16 Trays Food Dehydrator Machine | Mix Kitchen International

- 7 months ago

- Nigeria

- 54 Views

Industry Packaging Machine | The Hub’s Engineering Pte Ltd

- 7 months ago

- Singapore

- 61 Views

Food Warmer Display Machine | Mix Kitchen International

- 7 months ago

- Nigeria

- 56 Views

4 Trays 2 Decks Gas Oven | Mix Kitchen International

- 7 months ago

- Nigeria

- 63 Views

50 Kg Dough Mixer Machine / 1 Bag | Mix Kitchen International

- 7 months ago

- Nigeria

- 54 Views

Plastic Molds Manufacturer | Best Precision Tools

- 7 months ago

- Coimbatore North, Tamil Nadu, India

- 55 Views

Strainer Supplier in Australia | Australian valve

- 7 months ago

- Australia

- 52 Views

Filter Cloth Manufacturers | Makpol Industries

- 7 months ago

- Ghaziabad City, Uttar Pradesh, India

- 67 Views

Quality Plastic Components Manufacturer | Best Precision Tools

- 7 months ago

- Coimbatore North, Tamil Nadu, India

- 66 Views

Best Pigging System For Paint Industry | IUS

- 7 months ago

- Mumbai - Juhu, Maharashtra, India

- 51 Views

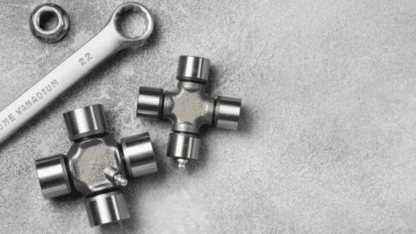

Medium Duty Axle Shafts | Talbros Engineering Limited

- 7 months ago

- Faridabad City, Haryana, India

- 55 Views

Spill Trays For Safe Secondary Containment | EcoSolutions

- 7 months ago

- UAE

- 48 Views

Commercial Bakery Equipment and Industrial Bakery Machines in USA | BakonUSA

- 7 months ago

- California, USA

- 130 Views

Power Transformers in Howrah | Makpower Transformer

- 7 months ago

- Howrah City, West Bengal, India

- 175 Views

Strainer Supplier in Australia | Australian Valve

- 7 months ago

- Australia

- 84 Views

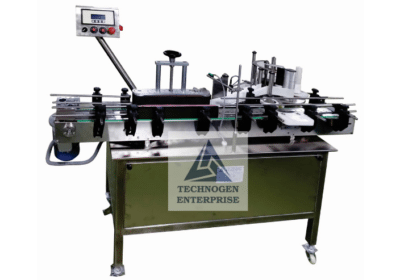

Round Bottle Sticker Labeling Machine | Technogen Enterprise

- 7 months ago

- Ahmadabad City, Gujarat, India

- 103 Views

Ball Valve Manufacturers | Sap Industries Ltd.

- 7 months ago

- Ahmadabad City, Gujarat, India

- 66 Views

Hydraulic Accumulator | Siken Hydraulics Inc.

- 7 months ago

- China

- 88 Views

Buy Pneumatic Equipment Online | Pneutube Limited

- 7 months ago

- UK

- 158 Views

Self Tapping Screws | Ejot Octaqon

- 8 months ago

- Gurgaon (Gurugram) City, Haryana, India

- 95 Views

Electric Chain Hoists | CarlstahlCraftsman.com

- 8 months ago

- Coimbatore South, Tamil Nadu, India

- 63 Views

Digital Liquid Filling Machine | Eminent Engineering Services

- 8 months ago

- Kolkata - Brace Bridge, West Bengal, India

- 64 Views

64 Trays Rotary Rack Oven | Mix Kitchen International

- 8 months ago

- Nigeria

- 61 Views

Best 9 Trays 3 Decks Gas Oven | Mix Kitchen International

- 8 months ago

- Nigeria

- 64 Views

Industrial Cake Showcase Chiller Machine | Mix Kitchen International

- 8 months ago

- Nigeria

- 113 Views

3 Steps Food Warmer Display Machine | Mix Kitchen International

- 8 months ago

- Nigeria

- 75 Views

6 Burners Industrial Gas Cooker with Oven | Mix Kitchen International

- 8 months ago

- Nigeria

- 65 Views

Industrial Bone Saw Machine | Mix Kitchen International

- 8 months ago

- Nigeria

- 104 Views

30 Cuts Dough Divider Machine | Mix Kitchen International

- 8 months ago

- Nigeria

- 76 Views

12 Trays Convection Baking Oven | Mix Kitchen International

- 8 months ago

- Nigeria

- 71 Views

3M 1110 | Ear Plugs Corded | PVC Foam | Disposable Earplugs | Pack of 100 | Sarvam Safety Equipment

- 8 months ago

- Chennai - Villivakkam, Tamil Nadu, India

- 67 Views

Karam Safety Helmet | PN 521 Shelmet | Ratchet Type | Violet | Sarvam Safety Equipment

- 8 months ago

- Chennai - Villivakkam, Tamil Nadu, India

- 132 Views

BANNA | Heat Resistant Upto 600 Degrees Spray Can 440ML | Matte Black | Sarvam Safety Equipment

- 8 months ago

- Chennai - Villivakkam, Tamil Nadu, India

- 64 Views

3M – 6200 | Half Facepiece | Reusable Respirator | Safety Mask | Sarvam Safety Equipment

- 8 months ago

- Chennai - Villivakkam, Tamil Nadu, India

- 97 Views

Trusted Seamless Pipe Wholesalers in India | JRS Iron and Steel

- 8 months ago

- Ghaziabad City, Uttar Pradesh, India

- 136 Views

Strainer Manufacturer in India | Speciality Valve

- 8 months ago

- Mumbai - Vashi, Maharashtra, India

- 85 Views

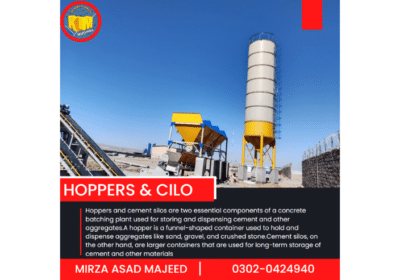

Hopper System | KM Mughal

- 8 months ago

- Pakistan

- 77 Views

Stainless Steel Plates | Bhakti Enterprises

- 8 months ago

- Mumbai - Bhiwandi, Maharashtra, India

- 78 Views

Leading Plastic Injection Molding Machine in India | Futech

- 8 months ago

- Bahadurgarh, Haryana, India

- 84 Views

3M 764 | Lane Marking Tape | Red 2″ x 36 Yards | Sarvam Safety Equipment

- 8 months ago

- Chennai - Villivakkam, Tamil Nadu, India

- 82 Views

Ceam Fitting Jig For 3D Concealed | BaiGapi.com

- 8 months ago

- UK

- 71 Views

High-Precision Liquid Filling Machine | Eminent Engineering Services

- 8 months ago

- Kolkata - Brace Bridge, West Bengal, India

- 98 Views

Robuste Prüfstandunterbauten für zuverlässige Lösungen

- 8 months ago

- Germany

- 67 Views

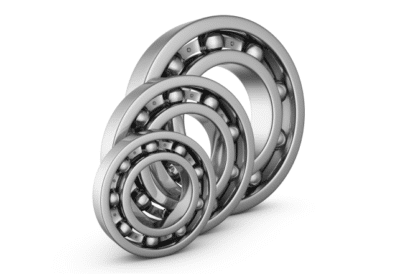

Buy Quality Ball Bearings in Delhi India | Kewa Bearing

- 8 months ago

- Delhi Cantonment, Delhi, India

- 115 Views

Dairy Product Display Cases in Canada | Econofrost

- 8 months ago

- Canada

- 85 Views

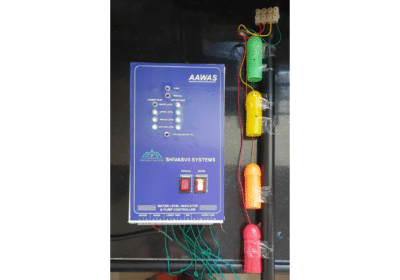

Water Level Indicator and Pump Controller

- 8 months ago

- Pune City, Maharashtra, India

- 90 Views

Dough Moulder Machine | Mix Kitchen International

- 8 months ago

- Nigeria

- 146 Views

16 Trays 4 Decks Gas Oven and 50 Kg Dough Mixer Machine | Mix Kitchen International

- 8 months ago

- Nigeria

- 111 Views

9 Trays 3 Decks Gas Oven | Mix Kitchen International

- 8 months ago

- Nigeria

- 146 Views

100 Kg Dough Mixer Machine | Mix Kitchen International

- 8 months ago

- Nigeria

- 163 Views

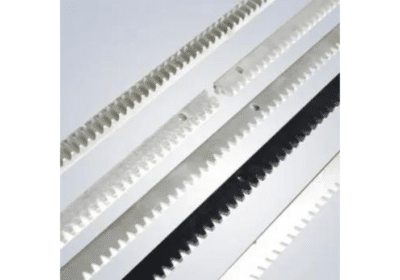

Premium Sliding Gate Gear Racks For Sale in China | WLY Transmission

- 8 months ago

- China

- 74 Views

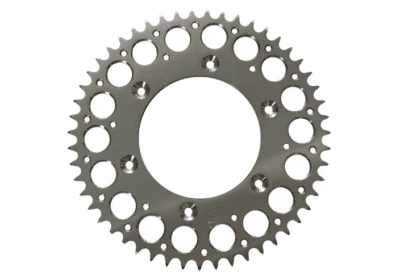

Upgrade Your Machinery with High-Quality Metric Sprockets

- 9 months ago

- China

- 81 Views

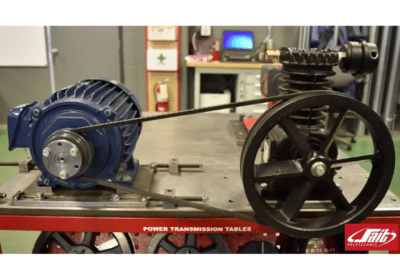

Looking For a Reliable V Belt Pulley?

- 9 months ago

- China

- 76 Views

Square and Round Billet Taper Measuring Instrument | Wuhan CenterRise

- 9 months ago

- China

- 68 Views

Big Bag Unloading System | Cybernetik Technologies

- 9 months ago

- Pune City, Maharashtra, India

- 115 Views

25/50/100 kg Dough Mixer Machine and 9 Trays 3 Decks Gas Oven | Mix Kitchen International

- 9 months ago

- Nigeria

- 412 Views

Ladle Lining Laser Thickness Gauge | Wuhan Center Rise M and C Engineering CO. Ltd.

- 9 months ago

- China

- 112 Views

Belt Type Oil Skimmer | Fenton Technologies Pvt. Ltd.

- 9 months ago

- Jaipur City, Rajasthan, India

- 73 Views

Food Packaging Automation Machine | Cybernetik Technologies

- 9 months ago

- Pune City, Maharashtra, India

- 104 Views

Buy Digital Surface Roughness Tester in Pakistan

- 9 months ago

- Pakistan

- 121 Views

Buy LR-G150 Rebar Scanner in Pakistan

- 9 months ago

- Pakistan

- 115 Views

Buy Uniphos Methyl Bromide Mbr-Lo Fumigation Gas Detector in Pakistan

- 9 months ago

- Pakistan

- 208 Views

Injection Molds Manufacturer Company in India | Best Precision Tools

- 9 months ago

- Coimbatore North, Tamil Nadu, India

- 77 Views

Buy Uniphos Phosphine PH3 Hi Phosphine Gas Detector in Pakistan

- 9 months ago

- Pakistan

- 123 Views

CA550 Chain For Sale in China – Premium Quality at Unbeatable Prices | WLY Transmission

- 9 months ago

- China

- 81 Views

Work From Home Business | EMI FACILITIES, BUY BACK PRODUCT.MACHINERY LOAN

- 9 months ago

- Kolkata - Salt Lake City, West Bengal, India

- 110 Views

Strat Your Own Business – EMI Facilities, Buy Back Product, Machinery Loan

- 9 months ago

- Kolkata - Salt Lake City, West Bengal, India

- 92 Views

Buy Top Quality Nut and Bolts in India | Rebolt Alloys

- 9 months ago

- Mumbai - Aare, Maharashtra, India

- 63 Views

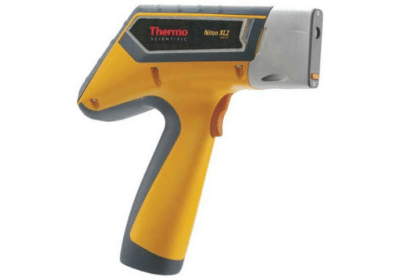

Buy Thermo Scientific Niton XL2 980 GOLDD XRF | Cerisky Store

- 9 months ago

- Argentina

- 126 Views

Shopping Mall Display Rack Manufacturers in Delhi | Aastu Refrigeration

- 10 months ago

- Delhi Cantonment, Delhi, India

- 65 Views

Stirrup Making Machine in India by SKZ Machinery

- 10 months ago

- Kannur City, Kerala, India

- 78 Views

Pigging System For Paint Industry | IUS Pigging Systems

- 10 months ago

- Mumbai - Worli, Maharashtra, India

- 122 Views

Industrial Pigging Systems | IUS Pigging System

- 10 months ago

- Mumbai - Andheri, Maharashtra, India

- 72 Views

Dungs Air Pressure Switch in India | De Novo

- 10 months ago

- Punjabi Bagh, Delhi, India

- 151 Views

List of Best Insulated Hand Tools Traders in UAE | Atninfo.com

- 10 months ago

- UAE

- 92 Views

Wire Bending and Forming Machine in India | SKZ Machinery

- 10 months ago

- Lucknow City, Uttar Pradesh, India

- 138 Views

Circle Blanking Line Manufacturer in India | SMT Parkash

- 10 months ago

- Gurgaon (Gurugram) City, Haryana, India

- 90 Views

Boom Barrier Dealers in Bhubaneswar | SKN IOT Technology

- 10 months ago

- Bhubaneswar (M.Corp.), Odisha, India

- 107 Views

3D CNC Wire Bending Machine in India | SKZ Machinery

- 10 months ago

- Mumbai - Bandra, Maharashtra, India

- 85 Views

AAC Machine Plants in India | BuildMate

- 10 months ago

- Hyderabad - Medchal, Telangana, India

- 78 Views

FBD Bag Manufacturers in India | Makpol Industries

- 10 months ago

- Ghaziabad City, Uttar Pradesh, India

- 90 Views

Food Processing Plants in India | Best Engineering Technologies

- 10 months ago

- Hyderabad - Nagole, Telangana, India

- 74 Views

Plastic Moulding Parts Manufacturer | Best Precision Tools

- 10 months ago

- Coimbatore North, Tamil Nadu, India

- 81 Views

Genteq Motor in Dubai | Prime Quality AC Spare Parts Trading LLC

- 10 months ago

- UAE

- 97 Views

CNC Rebar Cage Making Machine in India | SKZ Machinery

- 10 months ago

- Chennai - Perambur, Tamil Nadu, India

- 75 Views

Automatic Namkeen Fryer | Fry and Bake Technologies

- 10 months ago

- Ahmadabad City, Gujarat, India

- 72 Views

Potato Processing Equipment Company in India | Fry and Bake Technologies

- 10 months ago

- Ahmadabad City, Gujarat, India

- 114 Views

Display Racks Manufacturer in India | Aastu Refrigeration

- 10 months ago

- Delhi Cantonment, Delhi, India

- 105 Views

Supermarket Corner Rack Manufacturer in India | AASTU Refrigeration

- 10 months ago

- Delhi Cantonment, Delhi, India

- 65 Views

Stirrup Making Machine in India | SKZ Machinery

- 10 months ago

- China

- 81 Views

Planetary Gear Motor China | Sggearbox

- 10 months ago

- China

- 71 Views

ESE Lightning Aresster Manufacturers in India | Trisha Electrical

- 10 months ago

- Lucknow City, Uttar Pradesh, India

- 96 Views

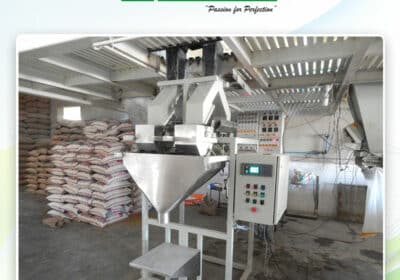

Are You Looking For Bagging Machine?

- 10 months ago

- Vadodara City, Gujarat, India

- 74 Views

Features of Compressed Air Filter Machine | GTS Filters And Systems (India) Pvt. Ltd.

- 10 months ago

- Vadodara City, Gujarat, India

- 85 Views

Industrial Pigging Systems | IUS Equipment

- 10 months ago

- Mumbai - Mumbai Central, Maharashtra, India

- 87 Views

Metal Detector Dealer in Jaipur | SS Communications

- 10 months ago

- Jaipur City, Rajasthan, India

- 71 Views

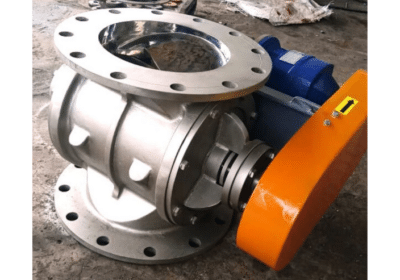

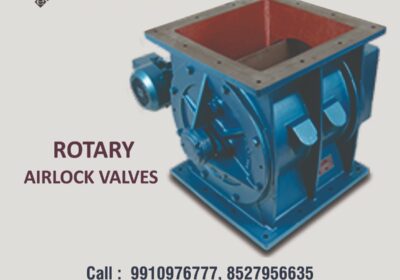

Rotary Airlock Valves | StratGem

- 10 months ago

- Pune City, Maharashtra, India

- 82 Views

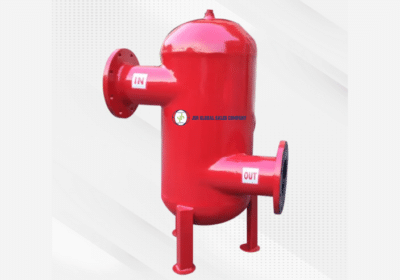

Air Separator Manufacturers – Efficient Air and Gas Removal Solutions

- 10 months ago

- Naraina Vihar, Delhi, India

- 83 Views

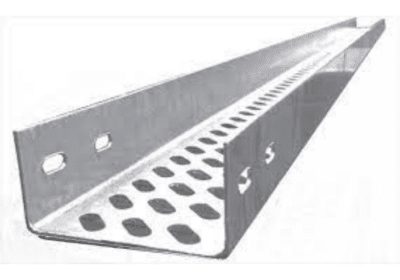

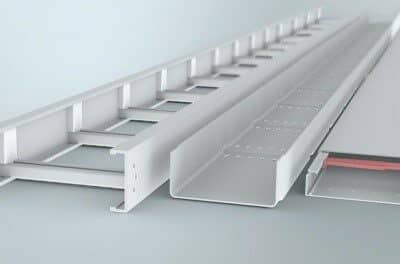

Buy High-Quality Cable Tray For Efficient Cable Management | Channel and Tray

- 10 months ago

- UK

- 65 Views

Transform Your Business with Armstrong’s Automated Storage and Retrieval Systems

- 10 months ago

- Pune City, Maharashtra, India

- 85 Views

Expansion Tank Manufacturers – Providing Reliable Thermal Expansion Solutions

- 10 months ago

- Naraina Vihar, Delhi, India

- 63 Views

Pressurization Pump Unit Manufacturers | JSR Global Sales

- 10 months ago

- Naraina Vihar, Delhi, India

- 88 Views

Carton Tapping Machine | Eminent Engineering Services

- 10 months ago

- Kolkata - Brace Bridge, West Bengal, India

- 103 Views

Industry Leading Suction Guide Manufactures | JSR Global Sales

- 10 months ago

- Naraina Vihar, Delhi, India

- 75 Views

Digital Granules Weigh Filler Machine in Kolkata | Eminent Engineering Services

- 10 months ago

- Kolkata - Brace Bridge, West Bengal, India

- 98 Views

Leading Gold Ingot Mold Manufacturers in India | Skytech Machine Tools

- 10 months ago

- Rajkot City, Gujarat, India

- 102 Views

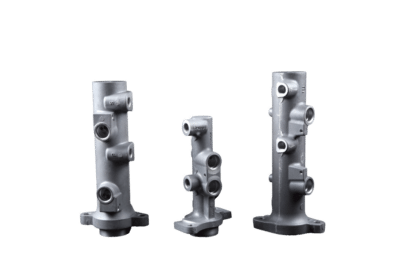

Investment Casting Manufacturers in India | ABI Showatech

- 11 months ago

- Chennai - Adambakkam, Tamil Nadu, India

- 79 Views

Fire Hydrant Companies in India | Secured Engineers

- 11 months ago

- Ludhiana (East), Punjab, India

- 67 Views

Looking For Top-Notch DC Gear Motors At Unbeatable Prices? SGMADA

- 11 months ago

- China

- 83 Views

Abrasive Blasting Equipment China | JX Abrasives

- 11 months ago

- China

- 80 Views

Socket Screws Supplies in UK | Fine Fit Fasteners

- 11 months ago

- UK

- 114 Views

Industrial Manufacturing Company in India | Mekark

- 11 months ago

- Chennai - Ashok Nagar, Tamil Nadu, India

- 78 Views

Fire Extinguisher Refilling Near Me | Vibrill Firesafe

- 11 months ago

- Noida City, Uttar Pradesh, India

- 84 Views

Industrial Gas Burner Dealers | De Novo

- 11 months ago

- Punjabi Bagh, Delhi, India

- 89 Views

Distribution Transformer Manufacturers in India | Servokon

- 11 months ago

- Laxmi Nagar, Delhi, India

- 70 Views

Laboratory Refrigerators Manufacturers in India | Elanpro

- 11 months ago

- Gurgaon (Gurugram) City, Haryana, India

- 92 Views

Wine Cooler | Elanpro

- 11 months ago

- Gurgaon (Gurugram) City, Haryana, India

- 87 Views

Fire Extinguisher Gas | Vibrill Fire Safe

- 11 months ago

- Noida City, Uttar Pradesh, India

- 96 Views

Looking For Top-Notch Gear Solutions at Unbeatable Prices?

- 11 months ago

- China

- 61 Views

Water Quality Monitors and Analyzers | Vasthi Instruments

- 11 months ago

- Guntur City, Andhra Pradesh, India

- 61 Views

Cigarette Making and Packing Machines | Orchid Tobacco Machinery

- 11 months ago

- UAE

- 87 Views

Humidity Test Chamber Manufacturer India | Yatherm Scientific

- 11 months ago

- Noida City, Uttar Pradesh, India

- 117 Views

DC Motor / DC Gear Motor at Best Price in China | SGMADA

- 11 months ago

- China

- 103 Views

Photo Stability Test Chamber Walk in Stability Test Chamber | Yatherm

- 11 months ago

- Noida City, Uttar Pradesh, India

- 99 Views

Purchase Champion Dual Fuel 4650 Watt Inverter Generator | Toleq.com

- 11 months ago

- Indonesia

- 71 Views

Best Gas Burner in India | De Novo India

- 11 months ago

- Punjabi Bagh, Delhi, India

- 89 Views

Champion 9200 Watt Generator with Electric Start | Toleq.com

- 11 months ago

- Indonesia

- 58 Views

Buy Cummins Onan 4500 Watt Digital Inverter Remote Electric Start Gasoline Portable Generator | Toleq.com

- 11 months ago

- Indonesia

- 56 Views

Are You Searching For The Perfect DC Gear Motor | SGMADA

- 12 months ago

- China

- 85 Views

Smart Electricity Meter For Injection Molding Machines | N2S Technolgies

- 12 months ago

- Chennai - Perungudi, Tamil Nadu, India

- 86 Views

Best Machine For Mopping | Cosmic Healers

- 12 months ago

- Chandigarh City, Chandigarh, India

- 69 Views

Thermal and Cable Solutions | Tempsens Instruments

- 12 months ago

- Udaipur City, Rajasthan, India

- 89 Views

Khoya Making Machine in India | NK Dairy Equipment

- 12 months ago

- Sonipat City, Haryana, India

- 80 Views

Injection Moulding Machine Manufacturers | Neelgiri Machinery

- 12 months ago

- Sonipat City, Haryana, India

- 78 Views

Mechanical Transmission Product Dealer | Tradelink Services

- 12 months ago

- Chennai - Padi, Tamil Nadu, India

- 90 Views

Storage Tank Manufacturer in India | NK Dairy Equipments

- 12 months ago

- Sonipat City, Haryana, India

- 61 Views

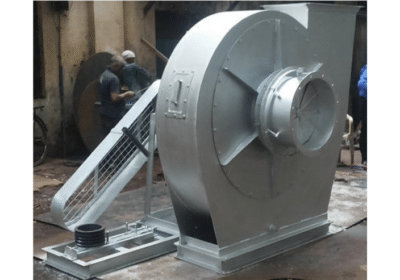

Industrial Air Blowers Manufacturers in India | Kay Blowers

- 12 months ago

- Sonipat City, Haryana, India

- 71 Views

Manual Chain Hoists: The Essential Guide | Bemco Pvt Ltd

- 12 months ago

- Mumbai - Kandivali, Maharashtra, India

- 94 Views

Servo Stabilizer Manufacturers in India | Power Line Systems

- 12 months ago

- Ghaziabad City, Uttar Pradesh, India

- 76 Views

Dry Mix Mortar Plant Manufacturer in India | BuildMate

- 12 months ago

- Hyderabad - Medchal, Telangana, India

- 90 Views

Best Hot Air Hopper Dryer | N2S Technologies

- 12 months ago

- Chennai - Perungudi, Tamil Nadu, India

- 86 Views

Best DC Gear Motor Manufacturer in China | SGMADA

- 12 months ago

- China

- 69 Views

Top Quality Industrial Gearbox Manufactures | JS Gears

- 12 months ago

- Ahmadabad City, Gujarat, India

- 74 Views

Low Cost Fully Automatic Paper Bag Making Machine | Ronald

- 12 months ago

- Faridabad City, Haryana, India

- 66 Views

Hot Air Hopper Dryer From N2S Technologies

- 12 months ago

- Chennai - Perungudi, Tamil Nadu, India

- 61 Views

Lockout Tagout Premium Quality at Cheap Rate | Lukko Safety

- 12 months ago

- Gurgaon (Gurugram) City, Haryana, India

- 62 Views

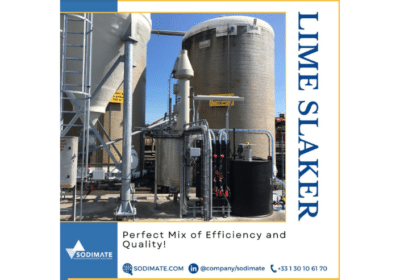

Lime Slaker System Manufacture | Sodimate

- 12 months ago

- California, USA

- 135 Views

Valve Manufacturer in China | Zhejiang VERVO Valve

- 1 year ago

- China

- 72 Views

Cranes Manufacturer in India | BuildMate

- 1 year ago

- Hyderabad - Medchal, Telangana, India

- 81 Views

Thread Protectors Exporters in UAE | DIC Oil & Gas Tools

- 1 year ago

- UAE

- 90 Views

Buy Commercial Tilting Grinder 10 Ltr in Coimbatore

- 1 year ago

- Coimbatore South, Tamil Nadu, India

- 64 Views

Filling Machines New Zealand | Proquip Solutions

- 1 year ago

- New Zealand

- 79 Views

Best FD Fan Manufacturers in India | Makpol Industries

- 1 year ago

- Ghaziabad City, Uttar Pradesh, India

- 103 Views

Pressure Vessel Manufacturer in China | DFC

- 1 year ago

- China

- 85 Views

Best Beer and Alcohol Liquor Making Equipment in India | S Brewings

- 1 year ago

- Bengaluru - Indiranagar, Karnataka, India

- 72 Views

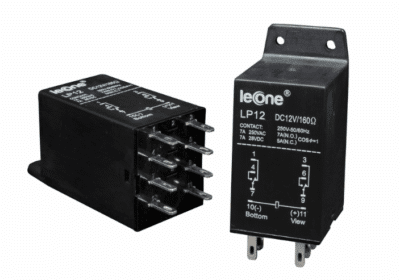

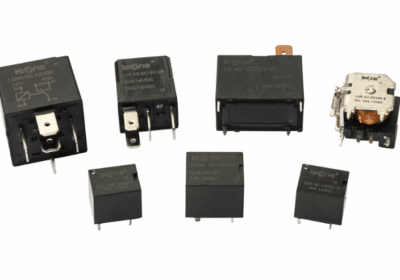

Get High-Quality Panel Relays in India | Leonerelays

- 1 year ago

- Palghar, Maharashtra, India

- 120 Views

Oval Spiral Duct Manufacturers Pune | Air Care System & Solution India Pvt. Ltd.

- 1 year ago

- Pune City, Maharashtra, India

- 86 Views

Bulk Milk Cooler Manufacturers & Suppliers in India | PlanetBaba.com

- 1 year ago

- Uttam Nagar, Delhi, India

- 91 Views

Best Beer and Alcohol Liquor Making Machinery in India | S Brewing Company

- 1 year ago

- Bengaluru - Agara, Karnataka, India

- 76 Views

Buy SS Round Bar | Hans Metal India

- 1 year ago

- Mumbai - Aare, Maharashtra, India

- 82 Views

Buy Turbo Blower in India | Kayblowers

- 1 year ago

- Sonipat City, Haryana, India

- 76 Views

Concrete Batching Plants Manufacturers in India | BuildMate

- 1 year ago

- Hyderabad - Medchal, Telangana, India

- 81 Views

Fuelless & Noiseless Generator in Nigeria | Windelectric Nigeria

- 1 year ago

- Nigeria

- 150 Views

Bakery Machine in Delhi | Swastik Professionals

- 1 year ago

- Naraina Vihar, Delhi, India

- 76 Views

Fuelless / Noiseless Generator in Lagos | Ecotech Ng

- 1 year ago

- Nigeria

- 469 Views

Searching For Flowmeters Services in NZ | Homersham

- 1 year ago

- New Zealand

- 101 Views

The Benefits of Using a Huck Bolt Machine | Macros Fastening Systems

- 1 year ago

- Howrah City, West Bengal, India

- 94 Views

Alfa Laval Industrial Centrifuge, Separator Machine and Spares MAB-103, 104

- 1 year ago

- Mumbai - Vashi, Maharashtra, India

- 94 Views

Top Machining Graphite Company in India | EXPO

- 1 year ago

- Noida City, Uttar Pradesh, India

- 92 Views

Best Machining Graphite Company in India | EXPO

- 1 year ago

- Noida City, Uttar Pradesh, India

- 95 Views

Industrial Safety Measurement Equipment | Vasthi Instruments

- 1 year ago

- Hyderabad - KPHB, Telangana, India

- 76 Views

Hypertherm MAXPRO200 Plasma Cutting System | EGP Sales

- 1 year ago

- Faridabad City, Haryana, India

- 101 Views

Top Welding Solution Providers in Gujarat | Patel Associates

- 1 year ago

- Ahmadabad City, Gujarat, India

- 83 Views

How to Choose the Right Conveyor Belt for Your Needs | Continental Belting

- 1 year ago

- Mumbai - Goregaon, Maharashtra, India

- 114 Views

Precision Plastic Injection Moulding | Best Precision Tools

- 1 year ago

- Coimbatore South, Tamil Nadu, India

- 86 Views

Plastic Molds Manufacturer Company in India | Best Precision Tools

- 1 year ago

- Coimbatore South, Tamil Nadu, India

- 113 Views

Urea Sugar Bagging Machine | Unipulse India

- 1 year ago

- Gurgaon (Gurugram) City, Haryana, India

- 115 Views

Robotic Palletizer For Loading & Unloading | TWSPL

- 1 year ago

- Vadodara City, Gujarat, India

- 97 Views

Industrial Evaporative Cooling System Supplier & Manufacturer in Pune, India

- 1 year ago

- Pune City, Maharashtra, India

- 110 Views

CNC EDM Wire Cut Machine Supplier in Pune | Berlin Machineries

- 1 year ago

- Jaipur City, Rajasthan, India

- 97 Views

Hydraulic Brake Press Machine Manufacturer in Pune | Berlin Machineries

- 1 year ago

- Pune City, Maharashtra, India

- 131 Views

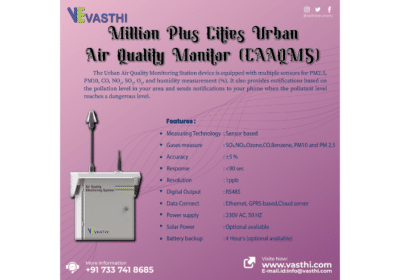

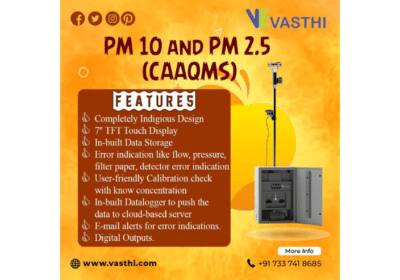

Continuous Ambient Air Quality Monitoring System (CAAQMS) – Vasthi Instruments

- 1 year ago

- Hyderabad - KPHB, Telangana, India

- 119 Views

CNC Fiber Laser Cutting Machine Supplier in India | Berlin Machineries

- 1 year ago

- Pune City, Maharashtra, India

- 113 Views

AAC Block Plants in Hyderabad | BuildMate

- 1 year ago

- Hyderabad - Medchal, Telangana, India

- 122 Views

Continuous Ambient Air Quality Monitoring System – Vasthi Instruments

- 1 year ago

- Hyderabad - Kukatpally, Telangana, India

- 152 Views

Ultrasonic Weather Monitoring Station

- 1 year ago

- Hyderabad - KPHB, Telangana, India

- 148 Views

Compact Cutting Solution – The Small Cutting Machine

- 1 year ago

- Faridabad City, Haryana, India

- 119 Views

CNC Machine Tools | Fuson Precision Machining

- 1 year ago

- California, USA

- 109 Views

Buy Metal Detector in Jaipur – SS Communications

- 1 year ago

- Jaipur City, Rajasthan, India

- 120 Views

Leading V Belt Supplier in UAE | Endura Hi-Tech

- 1 year ago

- UAE

- 198 Views

Graphite Product Manufacturers & Dealers in India

- 1 year ago

- Noida City, Uttar Pradesh, India

- 159 Views

Trolley Mounted Chain Pulley Block Features, Applications

- 1 year ago

- Mumbai - Kandivali, Maharashtra, India

- 186 Views

Buy Top-Notch Fasteners For Construction Project

- 1 year ago

- Jamnagar City, Gujarat, India

- 142 Views

Best Air Blower in India – KAY Blowers

- 1 year ago

- Sonipat City, Haryana, India

- 153 Views

GMT Special Application Chuck & Workholding

- 1 year ago

- Chennai - Pallikaranai, Tamil Nadu, India

- 126 Views

Lathe Machine Manufacturer in Kolkata

- 1 year ago

- Kolkata - Baghajatin, West Bengal, India

- 210 Views

Triple Eccentric Butterfly Valve Manufacturer in India

- 1 year ago

- Coimbatore North, Tamil Nadu, India

- 115 Views

Heat Transfer Fluid Manufacturer in India

- 1 year ago

- Ahmadabad City, Gujarat, India

- 126 Views

Vevor Many GEOs Affiliate Program

- 1 year ago

- Pune City, Maharashtra, India

- 173 Views

Stainless Steel Bolts Nuts Manufacturer in Surat

- 1 year ago

- Surat City, Gujarat, India

- 122 Views

Stainless Steel Fasteners Manufacturers in India

- 1 year ago

- Surat City, Gujarat, India

- 157 Views

Best Vacuum Pump Manufacturers in India

- 1 year ago

- Sonipat City, Haryana, India

- 110 Views

Paper Shredder Machine Price in Delhi

- 1 year ago

- Friends Colony, Delhi, India

- 134 Views

Top Vacuum Pump Manufacturers in India

- 1 year ago

- Ahmadabad City, Gujarat, India

- 180 Views

Top Quality Conveyor Belts in India

- 1 year ago

- Goregaon (Gondia), Maharashtra, India

- 162 Views

Top Forged Fitting Manufacturer in India

- 1 year ago

- Mumbai - Girgaon, Maharashtra, India

- 115 Views

Industrial Roller Chains Manufacturer & Supplier

- 1 year ago

- Narasimharajapura, Karnataka, India

- 121 Views

Tools & Equipment Supplier in Kenya – Metro Tools

- 1 year ago

- Kenya

- 517 Views

Best Electric Mopping Machine in India | Moppy

- 1 year ago

- Dera Bassi, Punjab, India

- 126 Views

Discover The Benefits of a PU Timing Belt

- 1 year ago

- Mumbai - Kamothe, Maharashtra, India

- 121 Views

Conveyor Belt Manufacturers in India

- 1 year ago

- Mumbai - Goregaon, Maharashtra, India

- 179 Views

Top Quality Huck Lock Bolting Machine in India

- 1 year ago

- Howrah City, West Bengal, India

- 109 Views

Top Meter Boxes Manufacturers in India

- 1 year ago

- Gautam Buddha Nagar City, Uttar Pradesh, India

- 119 Views

Best Platform For Sell Machinery Online

- 1 year ago

- California, USA

- 110 Views

Potential Transformers Suppliers in India

- 1 year ago

- Gautam Buddha Nagar City, Uttar Pradesh, India

- 141 Views

Servo Voltage Stabilizers Suppliers in India

- 1 year ago

- Gautam Buddha Nagar City, Uttar Pradesh, India

- 123 Views

Distribution Transformers Suppliers in India

- 1 year ago

- Gautam Buddha Nagar City, Uttar Pradesh, India

- 125 Views

Top Transformers Suppliers in India

- 1 year ago

- Gautam Buddha Nagar City, Uttar Pradesh, India

- 125 Views

Filter Pad Manufacturers in India

- 1 year ago

- Ghaziabad City, Uttar Pradesh, India

- 110 Views

Fiber Glass Filter Bag Manufacturer in India

- 1 year ago

- Ghaziabad City, Uttar Pradesh, India

- 160 Views

Best Packaging Strap Suppliers in India

- 1 year ago

- Rajkot City, Gujarat, India

- 136 Views

Filter Cage Manufacturers in India

- 1 year ago

- Ghaziabad City, Uttar Pradesh, India

- 129 Views

Top Stretch Film Suppliers in India | Pet Strap India

- 1 year ago

- Rajkot City, Gujarat, India

- 125 Views

Top PP Strap Suppliers in India | Pet Strap India

- 1 year ago

- Rajkot City, Gujarat, India

- 115 Views

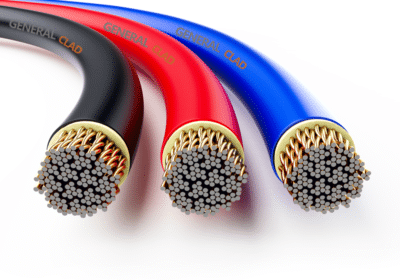

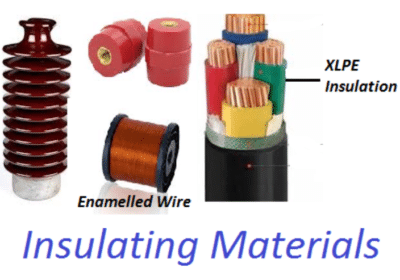

Best Brand of Wires & Cable in India | Paraflex

- 1 year ago

- Alwar City, Rajasthan, India

- 113 Views

ID Fan Manufacturers in India | Makpol Industries

- 1 year ago

- Ghaziabad City, Uttar Pradesh, India

- 132 Views

Top Polyester Strap Suppliers in India

- 1 year ago

- Rajkot City, Gujarat, India

- 138 Views

High Quality Paper Shredders at Best Price in Delhi

- 1 year ago

- Connaught Place, Delhi, India

- 146 Views

Buy Paper Shredder Machine at Affordable Price

- 1 year ago

- Connaught Place, Delhi, India

- 183 Views

Buy Best Hypertherm Consumables in India

- 1 year ago

- Faridabad City, Haryana, India

- 96 Views

Top Hypertherm Consumables Supplier in India

- 1 year ago

- Faridabad City, Haryana, India

- 94 Views

Canted Coil Spring Manufacturer in China

- 1 year ago

- China

- 140 Views

Best Electric Tow Tug For Sale in Chandigarh

- 1 year ago

- Chandigarh City, Chandigarh, India

- 134 Views

How To Install Press-Fit Ball Plunger

- 1 year ago

- California, USA

- 109 Views

Buy Cardboard Baler For Cardboard Recycling

- 1 year ago

- Australia

- 112 Views

Top MS Tube Suppliers in Secunderabad

- 1 year ago

- Hyderabad - Secunderabad, Telangana, India

- 115 Views

Anode Supplier in UAE | Horizon Marine Services LLC

- 1 year ago

- UAE

- 147 Views

Find List of Top Insulation Material in UAE – AtnInfo

- 1 year ago

- UAE

- 127 Views

Industrial 3D Scanning Services in Australia | Zeal CAD Service

- 1 year ago

- Australia

- 295 Views

Buy Weld Trimmer in India | Kelvin Enterprises

- 1 year ago

- Ashok Nagar, Delhi, India

- 143 Views

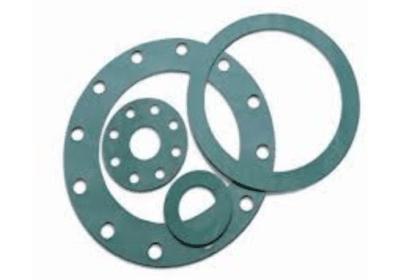

Top Gasket Manufacturer in Chennai | Max Well Industries

- 1 year ago

- Chennai - Adyar, Tamil Nadu, India

- 106 Views

Buy Explosion Proof Junction Box Online | Shree Electrical & Engineering Co.

- 1 year ago

- Mumbai - Thane, Maharashtra, India

- 91 Views

Industrial Water Chiller CWFL-3000 For 3KW Fiber Laser Cutting & Welding Machine

- 1 year ago

- Germany

- 104 Views

Industrial Water Chiller CW 6100 For 36KW CNC Spindle

- 1 year ago

- Germany

- 151 Views

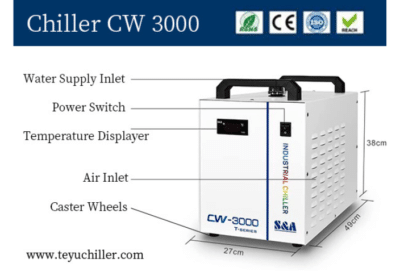

Mini Industrial Chiller Unit CW 3000 For CO2 Laser Engraving & Cutting Machines

- 1 year ago

- Germany

- 131 Views

Buy Heavy Duty Paper Shredder Machine in Delhi | Kavinstar

- 1 year ago

- Defence Colony, Delhi, India

- 103 Views

Buy Waste Management Equipments in Australia | Smart Waste Solutions

- 1 year ago

- Australia

- 134 Views

Cardboard Recycling in Australia | Smart Waste Solutions

- 1 year ago

- Australia

- 106 Views

Mono-Cum Rail Rod Trolley in India | Kelvin Enterprises

- 1 year ago

- Delhi Cantonment, Delhi, India

- 211 Views

Buy Paper Katran Machine / Buy Newspaper Katran Machine in Delhi | Kavinstar

- 2 years ago

- Dilshad Garden, Delhi, India

- 125 Views

Paper Shredder Machine Wholesalers in Delhi | Kavinstar

- 2 years ago

- Patparganj, Delhi, India

- 155 Views

Best Spiral Binding Machine Price in Delhi | Kavinstar

- 2 years ago

- Patparganj, Delhi, India

- 106 Views

Lamination Machine and Laminating Materials Supplier in Delhi | Kavinstar

- 2 years ago

- Andrews Ganj, Delhi, India

- 126 Views

Buy Best Quality Lamination Machine in Delhi | Kavinstar

Find Top Marine Offshore Electrical & Electronic Machine Traders in UAE | AtnInfo.com

- 2 years ago

- UAE

- 96 Views

Weld Trimmer Manufacturer in India | Kelvin Enterprises

- 2 years ago

- Delhi Cantonment, Delhi, India

- 178 Views

Buy Best Heavy Duty Paper Shredder Machine in Delhi | Kavinstar

- 2 years ago

- INA Colony, Delhi, India

- 123 Views

Best Shelving Storage Equipment in UAE | AtnInfo.com

- 2 years ago

- UAE

- 97 Views

Railway Track Inspection Trolley Manufacturer in Indonesia | Kelvin Enterprises

- 2 years ago

- Vasant Vihar, Delhi, India

- 128 Views

Top Quality Testing Instruments Manufacturer in India | Perfect Instruments

- 2 years ago

- Ghaziabad City, Uttar Pradesh, India

- 109 Views

Buy Best Heavy Duty Shredder Machine in Delhi | Kavinstar

- 2 years ago

- Defence Colony, Delhi, India

- 123 Views

Water Blasting Equipment For Sale in UAE | Speed Blast

- 2 years ago

- UAE

- 126 Views

OKM EXP 4500 Device to Detect Antiques and Platinum For Treasure Hunters | Golden Detector

- 2 years ago

- UAE

- 119 Views

Lamination Machine Price in Delhi | Kavinstar

- 2 years ago

- South Extension, Delhi, India

- 112 Views

Best Paper Shredding Machines Dealer and Supplier in Delhi | Kavinstar

- 2 years ago

- South Extension, Delhi, India

- 110 Views

Paper Shredder Machine Price in Delhi | Kavinstar

- 2 years ago

- Anand Parbat, Delhi, India

- 134 Views

Best Rubber Conveyor Belts Manufacturers in India | Modi Plus

- 2 years ago

- Bengaluru - Chickpet, Karnataka, India

- 132 Views

Buy Pneumatic Conveying System in UAE | Sodimate

- 2 years ago

- UAE

- 133 Views

Heavy Duty Paper Shredder Machine Price in Delhi | KAVINSTAR

- 2 years ago

- Lajpat Nagar, Delhi, India

- 152 Views

Molten Aluminum Pumps Manufacturer in India | Auro Pumps

- 2 years ago

- Bharuch City, Gujarat, India

- 150 Views

HVAC Installation in Mississauga, ON, Canada | Air Track Inc

- 2 years ago

- Canada

- 123 Views

Molten Lead Pumps Manufacturer in India | Auro Pumps

- 2 years ago

- Bharuch City, Gujarat, India

- 125 Views

Industrial Paper Shredder Machine Manufacturer in Delhi | Kavinstar

- 2 years ago

- South Extension, Delhi, India

- 121 Views

Buy Coin Operated Water Drinking Vending Machine in USA | Crystal Vending Machines

- 2 years ago

- California, USA

- 136 Views

Industrial Paper Shredder Machine Price in Delhi | Kavinstar

- 2 years ago

- Chanakya Puri, Delhi, India

- 162 Views

Lamination Machine Price in Delhi, Gurgaon, Noida, Ghaziabad and Faridabad | Kavinstar

- 2 years ago

- Lodhi Estate, Delhi, India

- 136 Views

Dual Speed Motor Dealers in Delhi | ANG Industries

- 2 years ago

- Delhi Cantonment, Delhi, India

- 153 Views

Grinder and Polisher Motor Dealers in Delhi | ANG Industries

- 2 years ago

- Delhi Cantonment, Delhi, India

- 167 Views

ABB Motor Dealers in Delhi | ANG Industries

- 2 years ago

- Delhi Cantonment, Delhi, India

- 173 Views

Worm and Helical Gear Box Dealer in Delhi | ANG Industries

- 2 years ago

- Moti Nagar, Delhi

- 155 Views

Best Articulated Boom Lift on Rental in Chennai | Swastik Corporation

- 2 years ago

- Bengaluru South, Karnataka

- 139 Views

Paper Cutter Machine Price in Delhi | Kavinstar

- 2 years ago

- Connaught Place, Delhi

- 162 Views

Heating Elements Manufacturers & Suppliers in United Kingdom | Thermic Edge

- 2 years ago

- UK

- 152 Views

Spiral Binding Machine Price in Delhi | Kavinstar

- 2 years ago

- South Extension, Delhi

- 131 Views

Heavy Duty Paper Shredder Machine Price in India | Kavinstar

- 2 years ago

- South Extension, Delhi

- 166 Views

Pilot Operated Pressure Reducing Valve Manufacturer | Valvesonly Europe

- 2 years ago

- Italy

- 156 Views

Top Quality Power Tools & Hand Tools Company in China | INGCO Global

- 2 years ago

- China

- 258 Views

Buy Wide Range of Tools For any Job | WOKIN

- 2 years ago

- China

- 227 Views

Buy Best Full Range of Professional Tools | TOLSEN WORLD

- 2 years ago

- China

- 121 Views

Stainless Steel Products Supplier and Manufacturer in India | Bullion Pipes

- 2 years ago

- Mumbai - Colaba, Maharashtra

- 138 Views

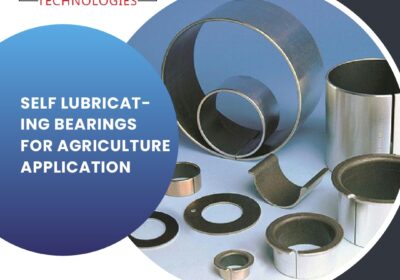

Best Self Lubricating Bearings in India | Awwa Technologies

- 2 years ago

- Bengaluru East, Karnataka

- 180 Views

Buy Multipurpose Machinery For Small Business in Jaipur, RJ | Freedom Enterprises

- 2 years ago

- Jaipur City, Rajasthan

- 151 Views

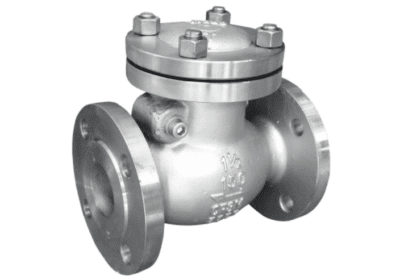

Swing Check Valve Manufacturer in USA | SVR Global

- 2 years ago

- USA

- 142 Views

Best Industrial Cooling Tower Manufacturer and Suppliers in India | World Cooling Towers

- 2 years ago

- Coimbatore South, Tamil Nadu

- 116 Views

Rotary Airlock Valves Manufacturer in India | Saksham Industrial Engineers

- 2 years ago

- Noida City, Uttar Pradesh

- 142 Views

Gate Valve Manufacturer in USA | SVR Global

- 2 years ago

- New Jersey, USA

- 299 Views

CNC Lathe Chuck | GMT Hydraulic Power Chucks

- 2 years ago

- Chennai - Guindy, Tamil Nadu

- 183 Views

Pilot Safety Valve Manufacturer in USA | SVR Global

- 2 years ago

- USA

- 196 Views

Pneumatic Knife Gate Valve Manufacturer in India | Speciality Valve

- 2 years ago

- Coimbatore South, Tamil Nadu

- 188 Views

Forged Steel Ball Valve Manufacturer in USA | SVR Global

- 2 years ago

- USA

- 156 Views

Auto Drain Valve For Compressor – Kisna Pneumatics Coimbatore

- 2 years ago

- Coimbatore South, Tamil Nadu

- 288 Views

Saraswati Spinning and Weaving Mills

- 2 years ago

- Nahan, Himachal Pradesh

- 228 Views

LENKAVANES Fit For Becker Vanes 90137301010 | WN 124-205

- 2 years ago

- Hyderabad - Ameerpet, Telangana

- 192 Views

Bulk Milk Cooler Manufacturer in Delhi

- 2 years ago

- Ghaziabad City, Uttar Pradesh

- 214 Views

L Sealer Machine – Worldpack Automation Systems Pvt. Ltd.

- 2 years ago

- Mumbai - Airoli, Maharashtra

- 225 Views

Anish Paper Products Paper Plate Making Machine

- 2 years ago

- Hyderabad - Amberpet, Telangana

- 275 Views

Leading Sanitary Casting Products Suppliers In India | Crescent Foundry

- 2 years ago

- Kolkata - Esplanade, West Bengal, India

- 355 Views

SIEMENS PLC, HMI AND OBSELETE SPARES AVAILABLE

- 2 years ago

- Gautam Buddha Nagar City, Uttar Pradesh

- 233 Views

Industrial RO Plant Manufacturer In Ahmedabad

- 2 years ago

- Ahmadabad City, Gujarat

- 236 Views

RECONDITIONED ALFA LAVAL INDUSTRIAL CENTRIFUGE

- 2 years ago

- Mumbai - Airoli, Maharashtra

- 288 Views

Alfa Laval Centrifuge, Oil Purifier, Oil Separator

- 2 years ago

- Mumbai - Airoli, Maharashtra

- 250 Views

ALL LEADING BRANDS OF INDUSTRIAL VALVES IN KOLKATA

- 3 years ago

- Kolkata - Strand Road, West Bengal

- 277 Views

Portable Water Chiller CWUP-20 for Ultrafast Laser

- 3 years ago

- China

- 298 Views

Air Cooled Rack Mount Chiller for Handheld Laser Welding Machine

- 3 years ago

- China

- 271 Views

Small Water Chiller CW5000 for CO2 Laser Engraver Cutter

- 3 years ago

- China

- 273 Views

You must be logged in to post a review.